Vacuum generator

Vacuum generator

The vacuum generator is driven by the compressed air (4-6bar) produced by the air compressor, which can produce a vacuum degree of - 100.8kpa at most. It is widely used in vacuum system and brings revolution to the field of vacuum automation.

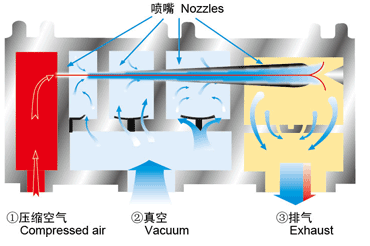

Working principle of vacuum generator

As shown in the figure above, the working principle is that the compressed air enters from the port ① and then exits from the exhaust port ③ through more than one vacuum chamber. The venturi phenomenon between the nozzles creates a vacuum in each chamber. When the vacuum chambers are integrated into port ②, air will be drawn in from port ②.

Selection method of vacuum generator

1. The flow of the vacuum generator refers to the air intake when the vacuum port is fully open under a standard atmospheric pressure.

2. The suction flow at this time is also called displacement flow or volume flow. Units are expressed in standard liters per minute, standard cubic feet per minute, or standard cubic meters per hour.

3. Select three elements of vacuum generator: vacuum flow (L / min), vacuum degree (bar) and practical use.

4. Flow calculation formula of vacuum generator:

S = 2.303* (V/T)*Log(P1/P2)

S: Vacuum flow (L / min)

5: Total volume from suction cup to vacuum generator (L)

T: Time to reach maximum vacuum (min)

P1: initial atmospheric pressure (bar)

P2: maximum vacuum degree (bar)

Advantages of vacuum generator

1. Use compressed air to drive to generate vacuum. No need for electricity, can be used in explosion-proof area.

2. No heat. The normal working temperature is - 20 ℃ ~ + 120 ℃.

3. Save energy. The ratio of compressed air consumption and vacuum air extraction is up to 1:3. After installing throttle valve, compressed air can be saved and vacuum degree can be reduced.

4. Small size and light weight. Easy to install in a small space.

5. Low noise. Compared with the vacuum pump with the same flow rate, the noise is only 53db ~ 56dB.

6. No vibration. It is widely used in the space which needs to avoid vibration.

7. There is no need for lubrication, and there is little hidden trouble. Therefore, there is no need for maintenance, unlike the motor-driven vacuum pump, which needs regular maintenance.

8. Fast reaction speed, suitable for frequent start-up. The reaction speed of the corresponding vacuum pump is very slow.

9. Strong environmental adaptability. The vacuum generator made of corrosion-resistant material is suitable for corrosive and dangerous environment.

10. There are many flow and vacuum degrees available. Flow range: 8L / min ~ 11928l / min. The maximum vacuum degree can reach - 100.8kpa (- 756mmhg).

11. Low cost. Equivalent to the same flow of vacuum pump price about a third. And there is a large stock.

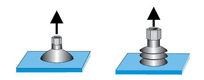

1、 Single stage vacuum generator

Single stage vacuum generator is a single nozzle vacuum generator, which is divided into common single nozzle vacuum generator, linear vacuum generator and integrated vacuum generator. Compared with the linear vacuum generator, the volume and flow rate of the common single nozzle vacuum generator are slightly larger, and the flow rate is slightly smaller compared with the multi-stage vacuum generator. The linear vacuum generator has the smallest volume and the smallest flow, and is usually connected in the middle of the air pipe. The integrated vacuum generator is developed to further compress the volume and reduce the failure rate of the gas pipe. It is generally composed of a single-stage vacuum generator, a vacuum filter, a silencer, a vacuum generation electromagnetic switch, a compressed air back blowing electromagnetic switch, a pressure sensor with vacuum setting function, a digital signal line with a standard interface, etc. These vacuum generators are widely used in electronic, automotive and other fields of automatic assembly line.

Characteristic

1. Medium: air

2. No lubrication required.

3. Air supply pressure: 0.4MPa ~ 0.6MPa

4. Working temperature: 0 ℃ ~ 60 ℃

2、 Multistage vacuum generator

Generally, it is a series parallel vacuum generator with three nozzles. It is characterized by saving compressed air, and the ratio of air consumption to vacuum air extraction of the multi-stage vacuum generator with reasonable structure can reach 1:3.

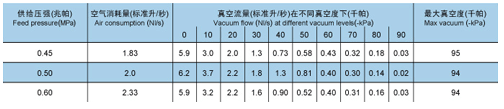

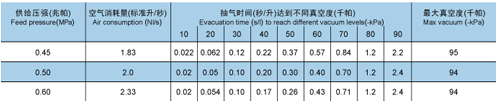

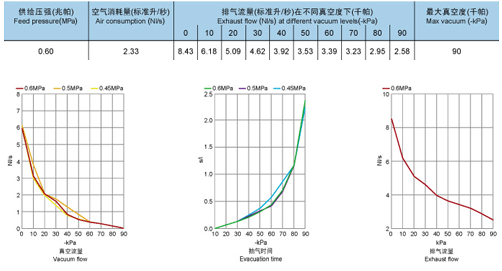

Characteristics of a single three-stage nozzle

1. The initial vacuum flow can reach 354 L / min.

2. The maximum air supply pressure is 0.7MPa.

3. The maximum vacuum is - 950 mbar.

4. When extracting 1 liter of air, the time to reach the maximum vacuum degree is 2.4 seconds.

5. The normal operating temperature range is - 10 ℃ ~ 80 ℃.

6. It is widely used.

Vacuum flow rate

Pumping time

Exhaust flow rate

What is a vacuum generator

What is a vacuum generator

Suction cup is a kind of pneumatic element which works by reducing the air pressure in the temporary sealing space formed after contacting with the workpiece and using the pressure difference between the inside and outside.

Working principle

The suction cup contacts with the workpiece to form a temporary closed space. Through the vacuum generating device, the pressure in the confined space is reduced, so that the internal pressure is lower than the external pressure. The pressure difference between inside and outside causes the vacuum sucker and the workpiece to be squeezed together. The greater the pressure difference between the inside and outside, the stronger the extrusion pressure, and the stronger the adsorption capacity of the suction cup. The pressure difference between inside and outside is reduced by increasing the pressure in the confined space, and the suction cup is separated from the workpiece. Based on the above principles, vacuum suction cups are generally used to carry and fix objects.

Material and classification

The material is generally rubber, plastic and metal. Common rubber materials include NR, NBR, Si, FKM, PUR, NE, EPDM, Se, etc. According to the shape, it can be divided into flat suction cup, elliptical suction cup, corrugated suction cup and special suction cup, among which corrugated suction cup can be further divided into 1.5 corrugated suction cup, 2.5 corrugated suction cup and multi corrugated suction cup; according to the way of reducing pressure, it can be divided into pneumatic suction cup and manual suction cup.

Material table

Characteristic

1、 Easy to lose. As it is generally made of rubber, it is in direct contact with objects and wears quickly, so it needs to be replaced frequently.

2、 Easy to use. No matter what material the workpiece is, it can be used as long as it can be sealed. Compared with the electromagnetic chuck, which can only be used for ordinary steel, it has outstanding advantages.

3、 No pollution. Vacuum suction cup does not produce light, heat and electromagnetic. It is especially environmentally friendly and will not pollute the environment.

4、 No damage to the workpiece. Due to its working principle and material characteristics, the vacuum suction cup will not cause any damage to the workpiece when it is adsorbed or released. Compared with hook type and wire rope type slings, the advantages of vacuum suction cup are obvious in the field of especially strict requirements for workpiece surface.

Calculation formula

1、 Calculate workpiece weight

m=L x W x H x ρ

M = mass (kg)

L = length (m)

W = width (m)

H = height (m)

ρ = density (kg / m3)

2、 Force on vacuum suction cup

1. The vacuum suction cup is horizontal and the force is vertical

Place the vacuum sucker on the horizontal workpiece and move vertically

Fth = m x (g+a) x s

FTH = theoretical grip (n)

M = mass (kg)

G = acceleration of gravity (9.81 M / S2)

A = acceleration of the handling system (m/s2)

Take emergency power off into account

S = safety factor - Minimum 1.5, rough porous and leaky surface ≥ 2.0

2. Vacuum suction level, force level

Place the vacuum sucker on the horizontal workpiece and move horizontally

Fth = mx(g+a/μ)xs = (mg+ma/μ)x s = (mg+Fa/μ)x s

FTH = theoretical grip (n)

FA = acceleration force = MxA

M = mass (kg)

G = acceleration of gravity (9.81 M / S2)

A = acceleration of the handling system (m/s2)

Take emergency power off into account

μ = friction coefficient

=0.1 oily surface

=0.2-0.3 wet surface

=0.5 wood, metal, glass, stone surface

=0.6 rough surface

S = safety factor - Minimum 1.5, rough porous and leaky surface ≥ 2.0

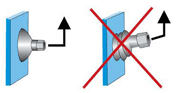

3. The vacuum suction cup is vertical and the force is vertical

Place the vacuum suction cup on the vertical workpiece and move vertically

Fth = m/μx(g+a)xs/y

FTH = theoretical grip (n)

FA = acceleration force = MxA

M = mass (kg)

G = acceleration of gravity (9.81 M / S2)

A = acceleration of the handling system (m/s2)

Take emergency power off into account

μ = friction coefficient

=0.1 oily surface

=0.2-0.3 wet surface

=0.5 wood, metal, glass, stone surface

=0.6 rough surface

S = safety factor - Minimum 1.5, rough porous and leaky surface ≥ 2.0

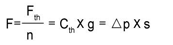

3、 Theoretical grip allocated to each suction cup

F = theoretical grip spread over each suction cup (n)

FTH = theoretical grip (n)

N = number of suction cups

CTH = theoretical weight of each suction cup (kg)

G = acceleration of gravity (9.81 M / S2)

△ P = internal and external pressure difference (bar)

Value equivalent to% vacuum

S = suction cup area (i.e. effective adsorption area) (cm2)

4、 Calculation of suction cup diameter

For circular suction cups only

D = diameter (mm)

FTH = theoretical grip (n)

N = number of suction cups

△ P = internal and external pressure difference (bar)

Value equivalent to% vacuum

Selection of suction cups

We consider it from three aspects: working environment, surface condition and operation mode. Working environment refers to corrosion, ozone, alcohol, temperature, etc.; surface condition refers to the roughness, porosity, oil, etc. of the workpiece surface; operation mode refers to the adsorption state, moving direction and operation frequency of the workpiece. According to the past experience, we will make a brief description of the application scope of various suction cups, hoping to help you in your choice.

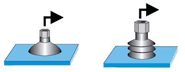

1、 Flat suction cup

It is suitable for a wide range of applications, especially when the workpiece needs to be turned over. Compared with the corrugated suction cup, the utility model has the advantages of small volume, smaller internal space and direct connection with the vacuum generator. When it is used for thin-walled workpiece, it will not cause permanent deformation; it can also better resist radial force under high acceleration; it can be used when the suction cup is parallel or perpendicular to the horizontal plane.

2、 Corrugated suction cup

It has good buffering property and can adapt to curved surface and uneven surface. Except for automobile suction cup, it is generally not allowed to be used perpendicular to the horizontal plane.

3、 Foam sucker

It has very good softness and can be applied to the workpiece with very rough surface.

4、 Special suction cup

It is suitable for workpieces with special requirements. We can provide corresponding solutions according to your specific requirements.

5、 Manual suction cup

Different from the above pneumatic suction cup, it does not need external air source. It adsorbs the workpiece by changing the shape of the suction cup itself or extracting the air inside the suction cup with a hand pump. There are two kinds of suction cups, one is plane suction cup and the other is curved suction cup. They are mainly used for handling and fixing the workpiece with very smooth surface, such as glass, stainless steel plate and painted objects.

6、 CD sucker

Most of them are closed ring or semi closed ring, mainly made of silica gel. Dedicated to the disc industry.

7、 High temperature resistant suction cup

Up to 400 ℃ (in a short time), suitable for high temperature steel plate, aluminum plate and glass plate.

8、 Sealing strip

It's a part of the ring suction cup. It is mainly used for rough surface workpieces, such as concrete prefabricated parts, refractory bricks, rough processed natural stones and ground glass, etc.

9、 Special suction cup for suction pen

All are flat thin lip suction cups, mainly made of conductive silica gel. It is mainly used for thin and light workpieces such as integrated blocks and solar cells.

10、 Non contact suction cup

It is especially suitable for very thin, porous or surface sensitive workpieces, such as paper, chips, solar cells, thin boards, printed circuit boards and films.