Vacuum generator

Vacuum generator

The vacuum generator is driven by the compressed air (4-6bar) produced by the air compressor, which can produce a vacuum degree of - 100.8kpa at most. It is widely used in vacuum system and brings revolution to the field of vacuum automation.

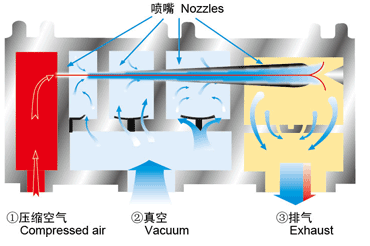

Working principle of vacuum generator

As shown in the figure above, the working principle is that the compressed air enters from the port ① and then exits from the exhaust port ③ through more than one vacuum chamber. The venturi phenomenon between the nozzles creates a vacuum in each chamber. When the vacuum chambers are integrated into port ②, air will be drawn in from port ②.

Selection method of vacuum generator

1. The flow of the vacuum generator refers to the air intake when the vacuum port is fully open under a standard atmospheric pressure.

2. The suction flow at this time is also called displacement flow or volume flow. Units are expressed in standard liters per minute, standard cubic feet per minute, or standard cubic meters per hour.

3. Select three elements of vacuum generator: vacuum flow (L / min), vacuum degree (bar) and practical use.

4. Flow calculation formula of vacuum generator:

S = 2.303* (V/T)*Log(P1/P2)

S: Vacuum flow (L / min)

5: Total volume from suction cup to vacuum generator (L)

T: Time to reach maximum vacuum (min)

P1: initial atmospheric pressure (bar)

P2: maximum vacuum degree (bar)

Advantages of vacuum generator

1. Use compressed air to drive to generate vacuum. No need for electricity, can be used in explosion-proof area.

2. No heat. The normal working temperature is - 20 ℃ ~ + 120 ℃.

3. Save energy. The ratio of compressed air consumption and vacuum air extraction is up to 1:3. After installing throttle valve, compressed air can be saved and vacuum degree can be reduced.

4. Small size and light weight. Easy to install in a small space.

5. Low noise. Compared with the vacuum pump with the same flow rate, the noise is only 53db ~ 56dB.

6. No vibration. It is widely used in the space which needs to avoid vibration.

7. There is no need for lubrication, and there is little hidden trouble. Therefore, there is no need for maintenance, unlike the motor-driven vacuum pump, which needs regular maintenance.

8. Fast reaction speed, suitable for frequent start-up. The reaction speed of the corresponding vacuum pump is very slow.

9. Strong environmental adaptability. The vacuum generator made of corrosion-resistant material is suitable for corrosive and dangerous environment.

10. There are many flow and vacuum degrees available. Flow range: 8L / min ~ 11928l / min. The maximum vacuum degree can reach - 100.8kpa (- 756mmhg).

11. Low cost. Equivalent to the same flow of vacuum pump price about a third. And there is a large stock.

1、 Single stage vacuum generator

Single stage vacuum generator is a single nozzle vacuum generator, which is divided into common single nozzle vacuum generator, linear vacuum generator and integrated vacuum generator. Compared with the linear vacuum generator, the volume and flow rate of the common single nozzle vacuum generator are slightly larger, and the flow rate is slightly smaller compared with the multi-stage vacuum generator. The linear vacuum generator has the smallest volume and the smallest flow, and is usually connected in the middle of the air pipe. The integrated vacuum generator is developed to further compress the volume and reduce the failure rate of the gas pipe. It is generally composed of a single-stage vacuum generator, a vacuum filter, a silencer, a vacuum generation electromagnetic switch, a compressed air back blowing electromagnetic switch, a pressure sensor with vacuum setting function, a digital signal line with a standard interface, etc. These vacuum generators are widely used in electronic, automotive and other fields of automatic assembly line.

Characteristic

1. Medium: air

2. No lubrication required.

3. Air supply pressure: 0.4MPa ~ 0.6MPa

4. Working temperature: 0 ℃ ~ 60 ℃

2、 Multistage vacuum generator

Generally, it is a series parallel vacuum generator with three nozzles. It is characterized by saving compressed air, and the ratio of air consumption to vacuum air extraction of the multi-stage vacuum generator with reasonable structure can reach 1:3.

Characteristics of a single three-stage nozzle

1. The initial vacuum flow can reach 354 L / min.

2. The maximum air supply pressure is 0.7MPa.

3. The maximum vacuum is - 950 mbar.

4. When extracting 1 liter of air, the time to reach the maximum vacuum degree is 2.4 seconds.

5. The normal operating temperature range is - 10 ℃ ~ 80 ℃.

6. It is widely used.

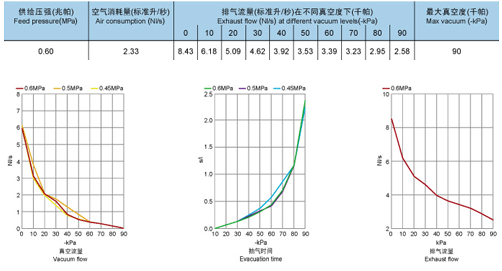

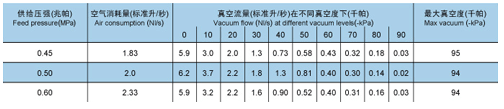

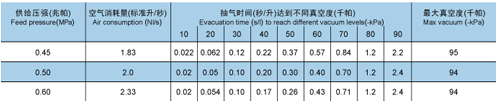

Vacuum flow rate

Pumping time

Exhaust flow rate